Characteristics of polyurethane sandwich panel

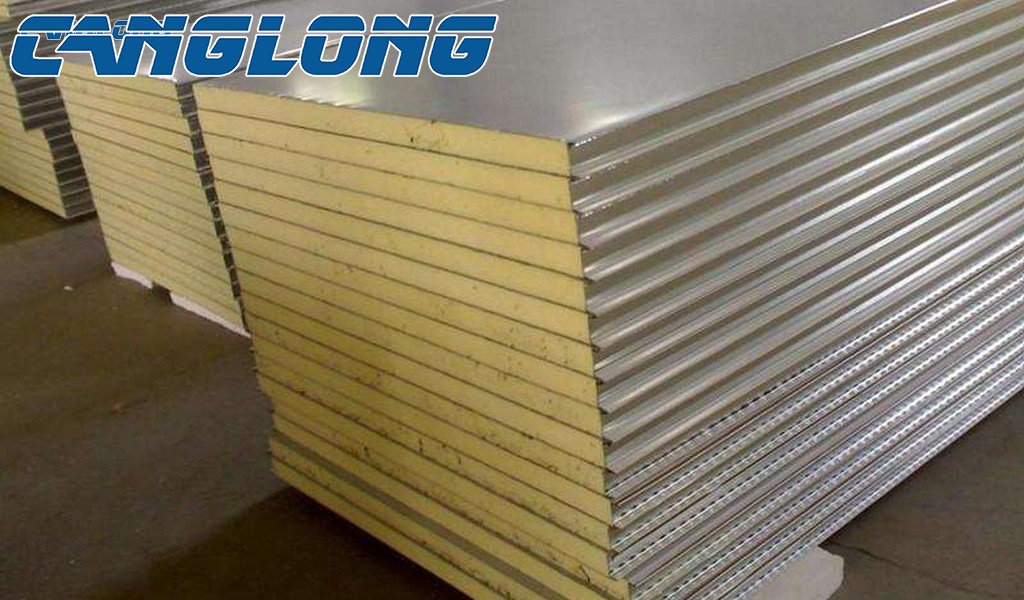

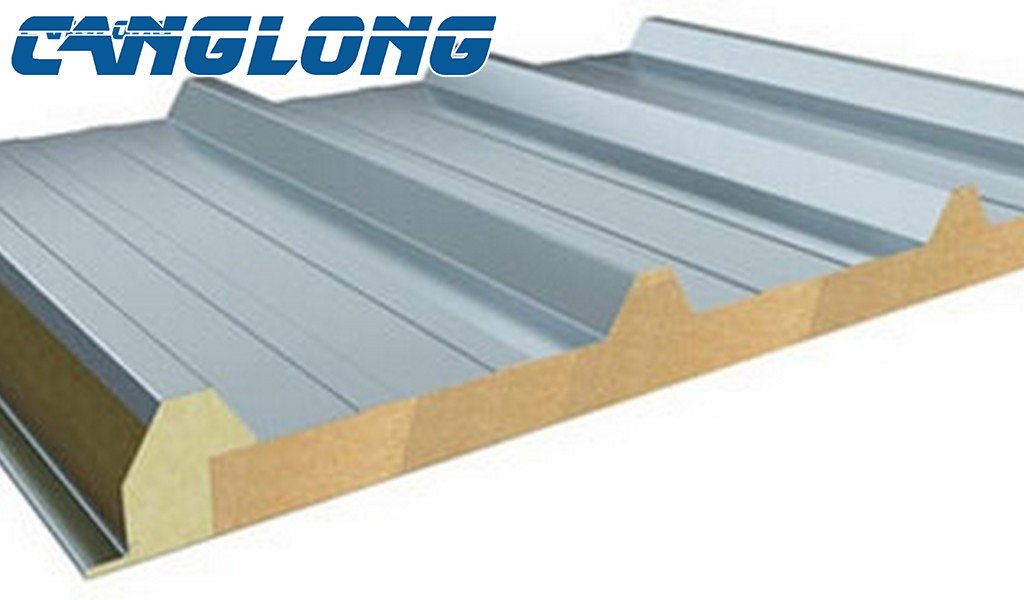

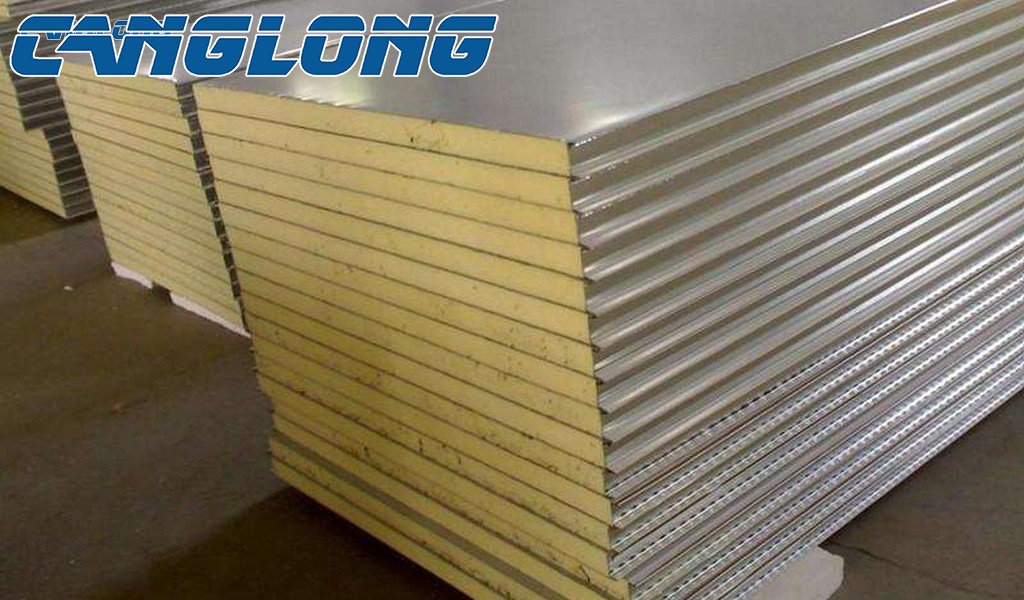

Polyurethane sandwich board is a bimetallic, single metal and non-metallic composite board with polyurethane hard foam as the insulation layer. It is usually used in the wall and roof enclosure system of industrial plants, logistics storage and integrated houses.

The production of polyurethane sandwich panel requires an advanced continuous production line of sandwich panel. The process is composed of internal and external galvanized (aluminum zinc plated) color steel plate cold bending forming and polyurethane hard foam coating in the middle.

Features of polyurethane sandwich panel produced by Canglong group:

1) Low thermal conductivity polyurethane sandwich board composite board has small thermal conductivity and good thermal insulation performance. It is the best thermal insulation material at present.

2) Beautiful plate shape and convenient installation

3) Good fire resistance

4) Non toxic and tasteless

5) Wide temperature range and good comprehensive benefit

6) Waterproof, moisture-proof, sound insulation, noise reduction, environmental protection, economy, fast construction, etc

The raw materials used by Canglong group are top material suppliers such as Huntsman, Shanghai Baosteel and Shandong guanbang. The company has an international leading technical team and R & D team. It uses international advanced production lines to produce polyurethane wallboard, roof board, dust-free board, cold storage board, side sealed rock wool fireproof board, polyurethane glass board and one-sided sealing board. Polyurethane sandwich panel has good cost performance advantages. It is a high-efficiency and energy-saving building envelope material with wide uses and great potential. It is also a new energy-saving panel advocated and promoted by the Ministry of construction.Sandwich panels are widely used in steel structure warehouses, workshops, fire prevention workshops, movable houses, chicken houses, cold storage rooms, fresh-keeping rooms, various purification rooms, air conditioning rooms, etc.

| STANDARD | PUR | PIR |

|---|---|---|

| CORE DENSITY | 38-43 | 45-50 |

| CLOSED CELL RATE | ≥97% | ≥97% |

| THERMAL CONDUCTIVITY | ≤0.023 | ≤0.023 |

| HEAT-RESISTANT RANGE |

-55-120℃ |

-50-160℃

|

| COMBUSION PERFORMANCE | ≥D | ≥B |