Unloading instructions for steel structure

The container unloading steel structure must be matched by large mechanical equipment, generally one crane with a weight greater than 50t and two forklifts with a lifting weight greater than 6T. Manual unloading shall be avoided. Due to the large weight of components, manual unloading is dangerous and the probability of fatal injury is high. During unloading, it is recommended to unload as a whole, which can effectively protect the quality of components and prevent deformation of components.

matters needing attention:

1. During the unloading of steel members, the unloading state must be observed at all times to prevent the deformation of members caused by improper dragging.

2. The unloading personnel shall keep a safe distance from the goods to prevent component collision or injury caused by improper operation.

3. Violent unloading is strictly prohibited.

4. The on-site command needs to be consistent, the command needs to be consistent, and follow the command.

List of necessary tools for unloading:

| Name | Reference picture | Specifications | Length | Quantity | Remarks |

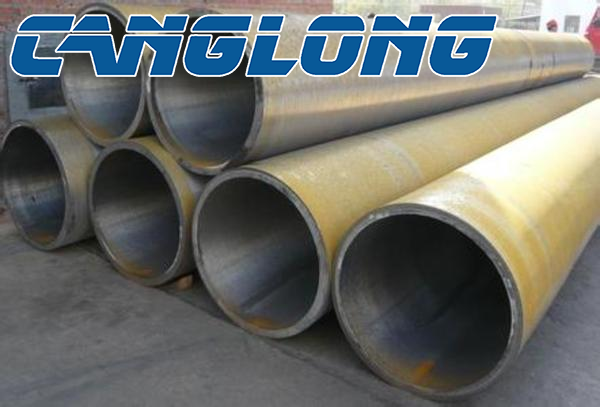

| Roller |

|

Diameter 200mm, wall thickness 30mm | 2 meters | 1 | seamless steel tube |

| A wire rope |

|

40mm diameter | 10 meters | Article 2 | Ring both ends |

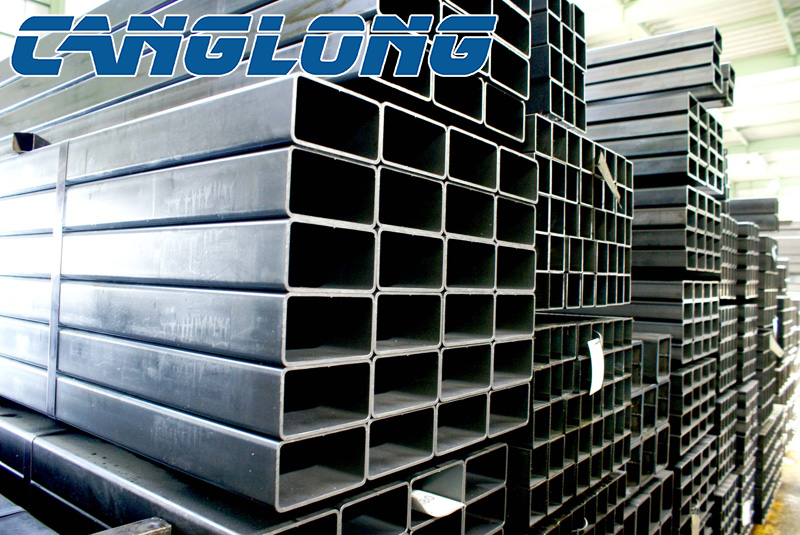

| Thin walled square tube |

|

40*80 | 7 meters | 2 | Thin wall 1.8mm thick |

| Ring chain |

|

15 meters | Article 1 |

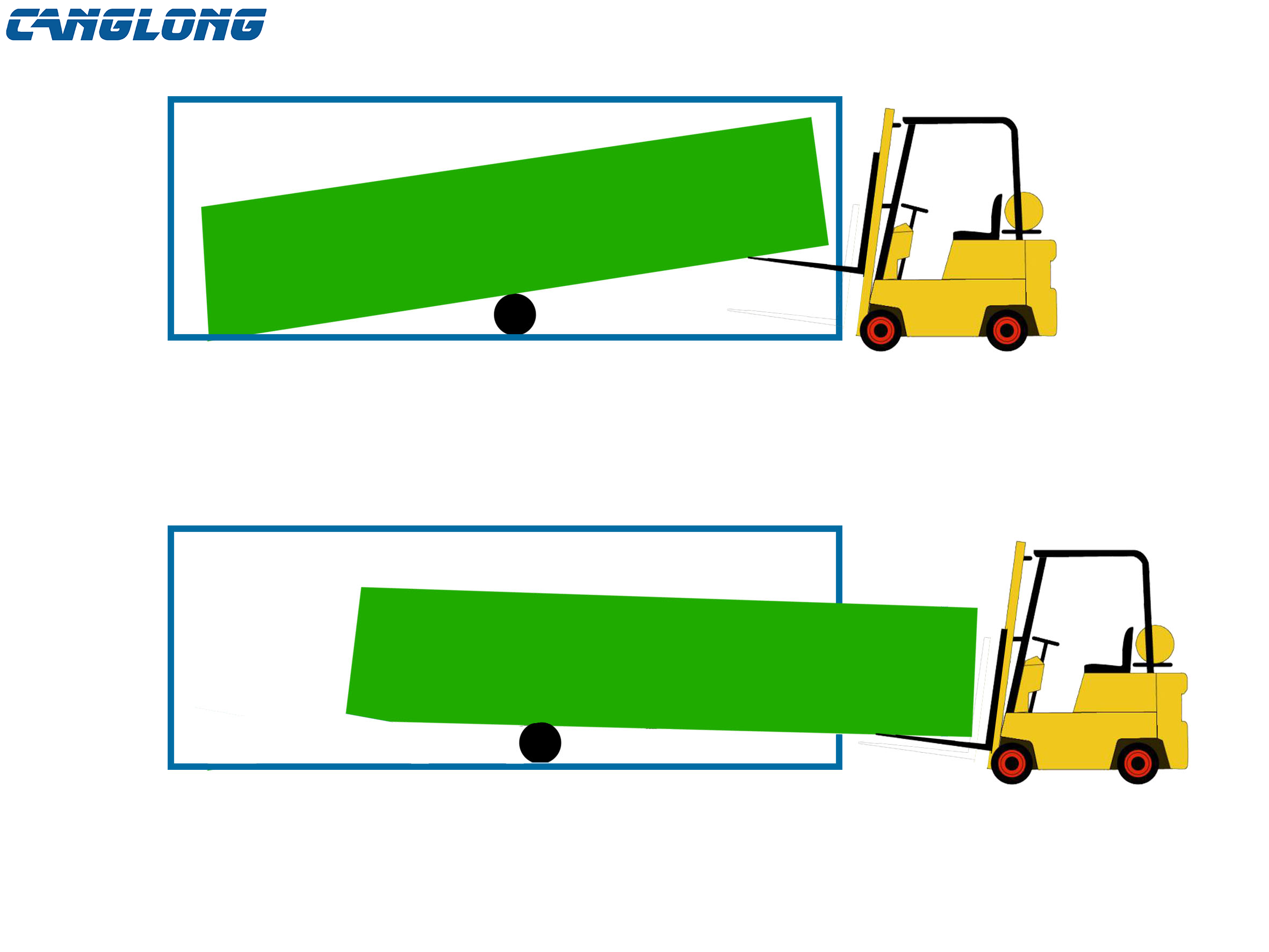

Step 2:

Open the container door, observe the load point of the goods, and prepare the unloading tools.

Lift the goods as a whole from the place closest to the bottom plate of the container with a forklift along the force bearing point (caution: do not pick small components, in principle, pick the largest).

Put the annular chain into the drum, and note that the annular chain should be of equal length on both sides.