5 kinds of color steel sandwich panels commonly used in metal buildings

Because of its light weight, convenient installation, durability, beautiful appearance, thermal insulation and other advantages, color steel sandwich panels have been widely used in construction site prefabricated rooms, factory buildings and other places. So how many types of color steel sandwich panels are commonly used in construction? Color plate manufacturers will talk about the 5 types of color steel sandwich panels.

Color steel sandwich panels generally have five types of EPS foam color steel sandwich panels, rock wool color steel sandwich panels, polyurethane sandwich panels, paper honeycomb sandwich panels and glass wool color steel panels.

EPS sandwich panel is an organic material, which has the characteristics of heat preservation, heat insulation, light weight and convenient installation. However, the foam sandwich panel has a disadvantage, that is, the material is easy to burn, so it is best not to use it in the construction of workshop partitions and factory buildings, because it cannot meet the fire protection requirements for these places.

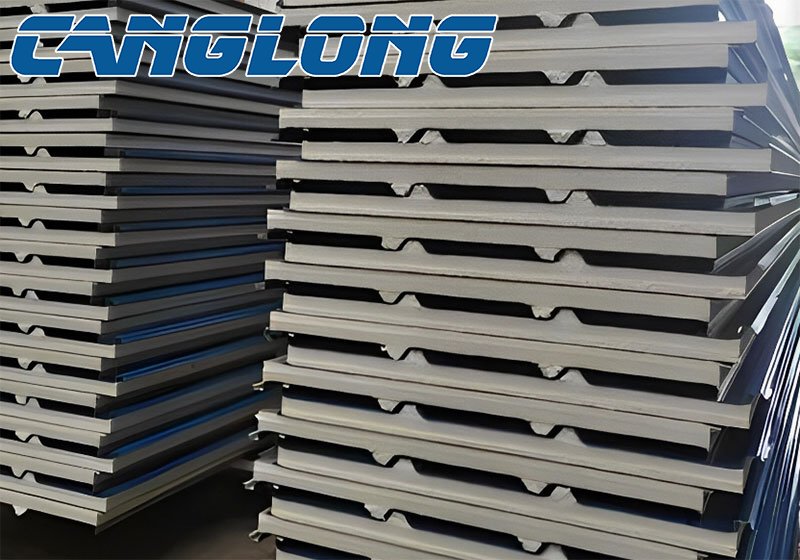

Rock wool color steel sandwich panel is a new type of fireproof panel with the strongest fire resistance in the color steel sandwich panel series. Rock wool sandwich panel is made of natural rock, blast furnace iron slag, etc., which are melted at high temperature into silk, and then solidified and formed. Rock wool color steel sandwich panel meets the second-class fire protection requirements of clean workshops, and is the most ideal structural decorative panel for interior ceiling and mobile room construction. Therefore, it is also the most popular color steel sandwich panel material among building materials in recent years. It has a fire-resistant performance of 600°C, and its fire-resistant rating reaches Class A, which is unmatched by polystyrene and polyurethane. Its core material is non-combustible rock wool.

Glass wool and phenolic foam sandwich color steel sandwich panels are slightly more expensive than foam and rock wool color steel panels. Phenolic foam polymer organic rigid aluminum foil foam products are foamed from thermosetting phenolic resin. It has the characteristics of light weight, fire prevention, non-combustibility, smokeless, non-toxic, non-drip, wide temperature range (-196~+200℃), no shrinkage and no embrittlement under low temperature environment, it is relatively high-end Material.

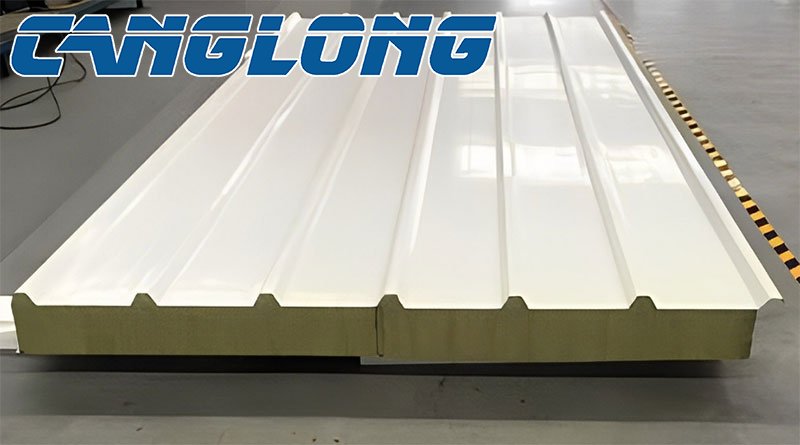

The polyurethane sandwich panel is composed of upper and lower layers of color steel plates and polyurethane foam in the middle, which has good thermal insulation, heat insulation and sound insulation effects, and the polyurethane added with fireproof materials does not support combustion.

Paper honeycomb sandwich panel products are composed of two layers of formed metal panels (or other material panels) and a polymer heat insulation core that is directly foamed and matured in the middle of the panels, which can prevent condensation of water vapor.

The above five types are relatively common color steel sandwich panels, and color steel sandwich panels have become an indispensable raw material in construction.

Latest News

-

Can metal sandwich panels be used as industrial high-temperature protection materials?

-

Steel structure warehouse: innovative solution for efficient storage and modern storage units

-

Packaged and shipped steel structure garage project for American clients

-

Customized steel structure garage: meeting diverse parking needs