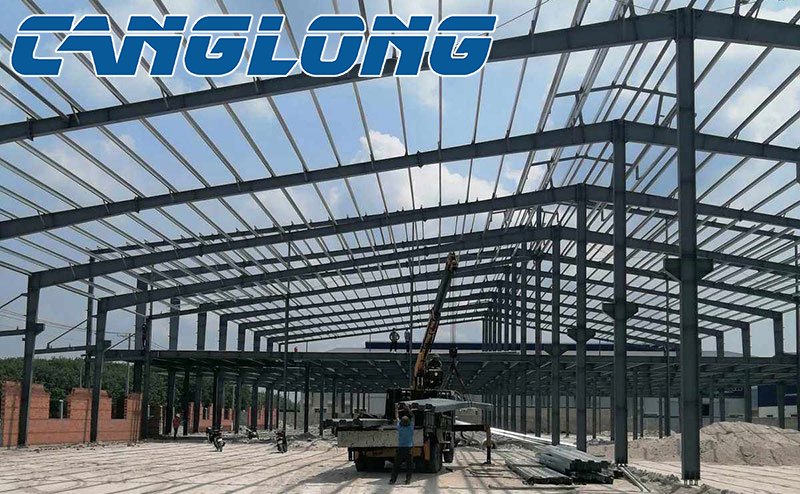

Installation of metal beams in portal steel frame warehouse

Steel structure inclined beam installation

1. Lifting method: The metal beam of the portal steel frame warehouse is characterized by a large span and a small lateral rigidity. In order to ensure quality, safety, improve production efficiency, and reduce labor intensity, according to the site and the capacity of the lifting equipment, the maximum expansion Assembling work, the inclined beam assembled on the ground is hoisted in place and connected with the column.

2. You can choose to lift at two points or three or four points with a single machine or use iron poles to reduce the pressure on the inclined beam generated by the rigging, or lift with two machines to prevent the lateral instability of the inclined beam.

3. Selection of lifting points: The lifting points of the metal beams of the large-span portal steel frame warehouse must be determined through calculation. For members with small lateral stiffness and large web-to-width ratio, prevent member distortion and damage. Mainly from the number of lifting points and the synchronization of the lifting of the two machines, the coordination of actions, consider pulling a wire rope between the hooks of the two machines when necessary, and the distance between the two machines is fixed when the hook is lifted to prevent mutual dragging.

4. At the connection point between the top and the steel frame, the end plate is placed vertically, horizontally or obliquely. The connections are all high-strength bolt connections, so the installation accuracy is required to be high.

5. The allowable deviation of the installation of the metal beams of the portal steel frame warehouse can be implemented in accordance with the relevant provisions of the steel structure engineering construction quality acceptance specification.