Comparison of differences between Q345 and Q355

Steel, as the core material of modern construction and manufacturing, is like the backbone of the industrial field, supporting the construction blueprint of countless great projects and precision products. In the vast world of construction, it casts the solid skeleton of high-rise buildings with its excellent strength and toughness. From the skyscrapers towering into the sky in the city skyline, their steel beams are like the bones of giants, steadily supporting the floors and facades, resisting the invasion of wind, rain, thunder and lightning, and the grinding of time. To the magnificent bridges, whether it is a beam bridge across the river, or a cable-stayed bridge or suspension bridge across the bay, the steel bridge structure can ensure the safe passage of vehicles and pedestrians with a strong bearing capacity, connecting cities and cities, land and islands.

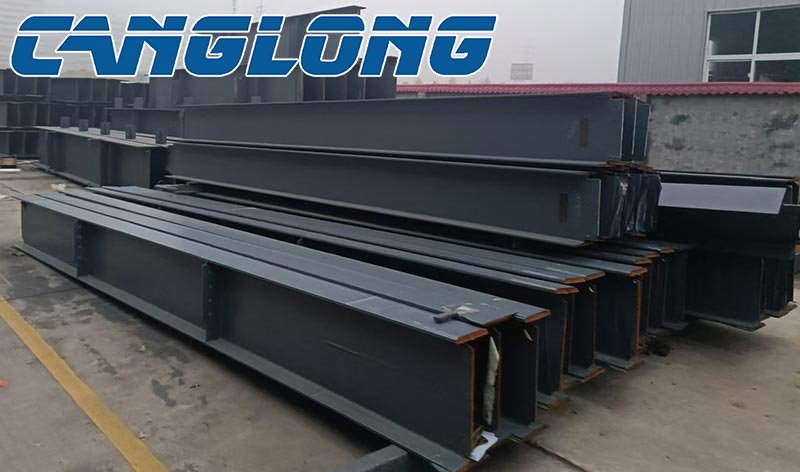

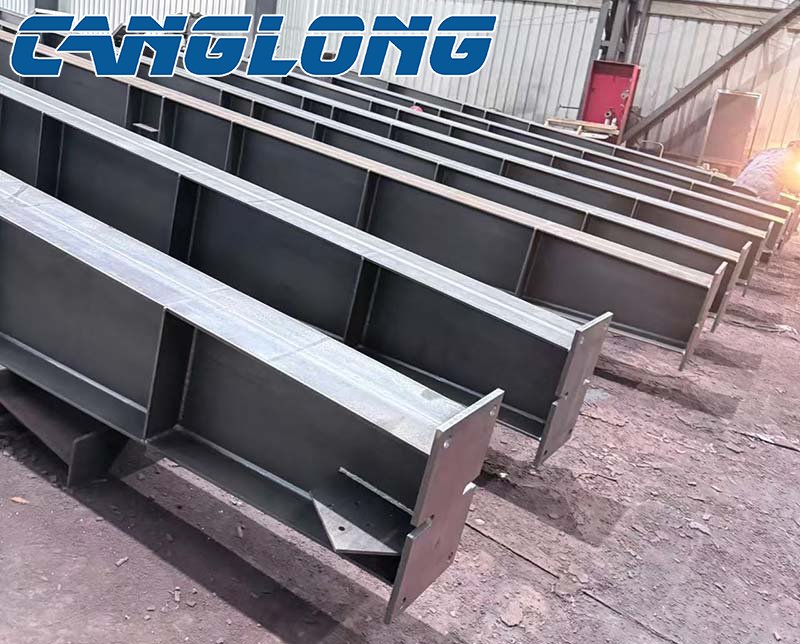

The quality of steel affects the quality and safety of the project. Steels such as Q345 and Q355 belong to the GB/T 1591 standard. In the construction field, this type of steel is used for the main load-bearing structures of large buildings, such as steel beams and steel columns of high-rise buildings, and the main structural parts of large bridges, because they can withstand large loads and have good comprehensive performance. So what are the differences between Q345 and Q355?

Chemical composition

Q345: It is a low-alloy high-strength structural steel, and its chemical composition mainly includes carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S) and other elements. The carbon content generally does not exceed 0.2%, the manganese content is between 1.00-1.60%, and the silicon content is about 0.20-0.55%. The reasonable ratio of these elements makes Q345 steel have good strength and toughness.

Q355: It is also a low-alloy high-strength structural steel. Compared with Q345, the adjustment of its chemical composition is mainly reflected in the relatively stable and slightly lower carbon content, generally below 0.24%, and the manganese content has increased to 1.00-1.70%. At the same time, the control of impurity elements such as phosphorus and sulfur is more stringent. For example, the phosphorus content does not exceed 0.030%, and the sulfur content does not exceed 0.030%. This optimization of chemical composition makes Q355 steel have better comprehensive performance in strength and toughness.

Mechanical properties

Yield strength

Q345: Its standard value of yield strength is 345MPa. In practical applications, this strength grade can meet the bearing requirements of many general structures, such as the frame structure of some medium-sized buildings, the supporting parts of ordinary machinery, etc.

Q355: The standard value of yield strength reaches 355MPa, which is a certain improvement compared with Q345. This makes Q355 more advantageous in structures that bear larger loads, such as the main beams of large bridges, the booms of heavy cranes, and other structures, which require higher yield strength to ensure the safety and reliability of the structure.

Tensile strength

Q345: The tensile strength is generally between 470 and 630MPa. It can show good performance when subjected to tensile loads, but it may be slightly insufficient in some occasions where higher tensile strength is required.

Q355: The tensile strength range is roughly 490-650MPa, which is slightly higher than Q345. This means that Q355 has more advantages in resisting tensile deformation and fracture, and is more suitable for components that bear larger tensile forces, such as cable structures, tension rods, etc.

Elongation

Q345: The elongation is generally not less than 21%. This shows that Q345 has a certain plasticity during the stress deformation process, and can absorb energy to a certain extent to prevent the material from breaking suddenly.

Q355: The elongation is not less than 22%, which is slightly higher than Q345. This makes Q355 perform better in terms of toughness, and it is less likely to suffer brittle fracture when subjected to dynamic loads or complex stress states, which is more conducive to the safety of the structure.

Application Scope

Q345: Widely used in the construction field, such as steel beams, steel columns and other structural components of general multi-story buildings. In mechanical manufacturing, it can be used to manufacture brackets and bases for some small and medium-sized mechanical equipment. It can also be used to manufacture ordinary vehicle frames and other structures. In these application scenarios, the strength and performance of Q345 can meet the basic use requirements.

Q355: Due to its higher strength and better toughness, it is mainly used in large-scale projects with higher requirements for structural safety performance. For example, it is widely used in key load-bearing structures of high-rise buildings, roof trusses of large stadiums, and main structures of cross-sea bridges. In the energy field, Q355 steel is often used in structures with extremely high strength and toughness requirements, such as wind turbine towers.

Welding performance

Q345: It has good welding performance and can be welded smoothly under general welding process conditions, such as manual arc welding, gas shielded welding, etc. However, during the welding process, it is necessary to pay attention to controlling the welding parameters to avoid problems such as embrittlement in the heat affected zone of the welding.

Q355: The welding performance is also good, but due to its chemical composition and mechanical properties, the requirements for welding technology are relatively higher during welding. For example, it is necessary to more accurately control parameters such as preheating temperature and welding line energy to ensure the quality of the welded joint and prevent defects such as welding cracks.

Latest News

-

Can metal sandwich panels be used as industrial high-temperature protection materials?

-

Steel structure warehouse: innovative solution for efficient storage and modern storage units

-

Packaged and shipped steel structure garage project for American clients

-

Customized steel structure garage: meeting diverse parking needs